The Book of Lilith PDF: A Comprehensive Overview (Updated 12/31/2025)

Exploring “The Book of Lilith” involves navigating a complex web of folklore‚ interpretations‚ and digital accessibility. Numerous online sources offer access‚

but verifying legality and source trustworthiness is crucial when seeking a PDF version of this intriguing text.

The digital landscape presents both opportunities and risks; caution is advised when downloading from unverified platforms‚ as malware and copyright infringements are potential concerns.

Understanding the myth’s evolution‚ from its roots in Jewish folklore to its modern literary representations‚ enhances appreciation for the diverse perspectives contained within “The Book of Lilith”.

What is “The Book of Lilith”?

“The Book of Lilith” isn’t a singular‚ canonical text like established religious scriptures. Instead‚ it generally refers to collections of texts and interpretations centered around the figure of Lilith‚ drawn primarily from the Alphabet of Ben Sira – a medieval Jewish text. These compilations explore Lilith’s story‚ expanding upon her brief mention in Jewish folklore as Adam’s first wife‚ who left him due to disagreements over equality.

The narratives often portray Lilith as a powerful‚ independent‚ and rebellious figure‚ embodying female strength and challenging patriarchal norms. Modern interpretations frequently view her as a symbol of female sexuality‚ freedom‚ and a connection to the natural world. The “book” as commonly understood‚ therefore‚ is a compilation of myths‚ legends‚ and scholarly analyses surrounding this enigmatic character.

Finding a definitive “Book of Lilith” PDF can be misleading‚ as many versions are curated anthologies or individual interpretations. These resources delve into Lilith’s representation as chaos‚ seduction‚ and even ungodliness‚ while simultaneously exploring her appeal as a feminist icon. The core of these texts examines her rejection of subservience and her embrace of autonomy‚ themes resonating strongly with contemporary audiences.

Historical Context and Origins

The origins of the Lilith myth predate the widespread availability of PDF versions of related texts‚ tracing back to ancient Mesopotamian demonology and early Jewish folklore. While Lilith doesn’t appear in the canonical Hebrew Bible‚ references to a nocturnal demoness with a similar name exist in earlier writings. The most significant source material emerged during the medieval period‚ specifically with the Alphabet of Ben Sira (around the 8th-10th centuries CE).

This text‚ presented as a moralizing letter‚ introduces the story of Lilith’s creation alongside Adam‚ her demand for equality‚ and her subsequent departure from the Garden of Eden. The narrative served as a cautionary tale‚ particularly concerning childbirth and infant mortality‚ attributing these issues to Lilith’s vengeful spirit.

The proliferation of “The Book of Lilith” as a collected work is a relatively recent phenomenon‚ fueled by 20th and 21st-century feminist and occult movements. The accessibility of digital formats‚ including PDFs‚ has further disseminated these interpretations‚ allowing for wider exploration of Lilith’s complex and evolving mythology. Modern scholarship continues to analyze the historical and cultural contexts shaping her story.

The Lilith Myth in Jewish Folklore

Within Jewish folklore‚ Lilith evolved from a minor demonic figure into a potent symbol of female independence and rebellion. Early Kabbalistic texts expanded upon the Alphabet of Ben Sira’s narrative‚ portraying Lilith as a dangerous seductress and mother of demonic offspring. The association with infant mortality led to amulets and incantations designed to ward off her influence‚ particularly during childbirth – a practice reflected even in discussions surrounding PDF versions of related texts today.

The myth served as a cultural explanation for unexplained infant deaths and anxieties surrounding female sexuality. Lilith’s refusal to submit to Adam’s authority resonated with societal fears about women challenging patriarchal norms. She became a figure of both fascination and condemnation‚ embodying both power and transgression.

The accessibility of “The Book of Lilith” in PDF format has allowed for a renewed interest in these folkloric origins‚ prompting reinterpretations and reclaiming of Lilith as a feminist icon. However‚ it’s crucial to remember the historical context of these narratives and the often-negative portrayals within traditional Jewish beliefs.

Lilith’s Representation: Chaos‚ Seduction‚ and Ungodliness

Lilith’s representation consistently revolves around themes of chaos‚ potent seduction‚ and perceived ungodliness‚ deeply ingrained within the folklore surrounding her. This portrayal‚ readily accessible through digital copies like the “Book of Lilith” in PDF format‚ stems from her rejection of subservience and embrace of autonomy. She embodies a primal‚ untamed force‚ contrasting sharply with the idealized image of Eve.

Her seductive nature isn’t presented as alluring‚ but rather as dangerous and threatening‚ often linked to nocturnal emissions and the harming of infants. This association fueled anxieties and superstitions‚ leading to protective rituals and beliefs. The availability of the text as a PDF allows modern readers to analyze these historical fears.

The “ungodliness” attributed to Lilith arises from her defiance of divine order and her refusal to accept a subordinate role. Exploring these representations within the PDF version of the text reveals a complex figure‚ simultaneously demonized and empowering‚ challenging conventional notions of good and evil.

The Absence of Lilith in the Canonical Bible

Notably‚ the name Lilith does not appear within the accepted texts of the canonical Bible‚ a crucial point when examining sources like the “Book of Lilith” available in PDF format. Her story originates outside of mainstream biblical scripture‚ developing instead within Jewish folklore and apocryphal texts‚ such as the Alphabet of Ben Sira.

This absence contributes to the ongoing debate surrounding her legitimacy as a historical or theological figure. The PDF versions circulating online often include extensive footnotes and commentaries addressing this very issue‚ clarifying her origins and the reasons for her exclusion from the biblical canon.

The lack of direct biblical reference doesn’t diminish Lilith’s cultural impact; rather‚ it highlights the power of oral tradition and alternative narratives. Accessing the “Book of Lilith” as a PDF allows researchers and enthusiasts to explore these alternative interpretations and understand how her myth evolved independently of official religious doctrine.

Genesis and the Creation of Eve: Contrasting Narratives

The traditional Genesis account of Eve’s creation – formed from Adam’s rib – sharply contrasts with the narrative surrounding Lilith‚ as detailed in texts like “The Book of Lilith” often found in PDF format. Lilith’s story posits her as Adam’s first wife‚ created simultaneously and equally from the earth‚ rejecting subservience and ultimately leaving the Garden of Eden.

This fundamental difference in origin stories is central to understanding Lilith’s symbolism. The PDF versions of the “Book of Lilith” frequently analyze this contrast‚ highlighting Lilith’s representation of female independence and challenging the patriarchal interpretations of Genesis.

Exploring these differing narratives reveals a fascinating tension within religious and cultural interpretations of creation. The availability of “The Book of Lilith” as a PDF provides access to a counter-narrative‚ prompting readers to question established doctrines and consider alternative perspectives on the origins of humanity and gender roles. It’s a compelling exploration of biblical interpretation.

The Alphabet of Ben Sira: The Primary Source

“The Alphabet of Ben Sira‚” a medieval Jewish text‚ stands as the primary source for the widely circulated Lilith myth. Many PDF versions of “The Book of Lilith” available online heavily draw upon‚ and often translate excerpts from‚ this foundational work. It details Lilith’s creation‚ her dispute with Adam over equality‚ and her subsequent departure from Eden.

Understanding the origins within “The Alphabet of Ben Sira” is crucial when examining any PDF compilation or analysis of the Lilith story. These digital texts often present interpretations layered upon this original narrative‚ sometimes expanding upon it with Kabbalistic or occult elements.

Researchers and enthusiasts seeking a deeper understanding of Lilith frequently consult digitized versions of “The Alphabet of Ben Sira” alongside “The Book of Lilith” PDFs. Accessing these primary sources allows for a more nuanced comprehension of the myth’s evolution and its enduring impact on folklore and cultural imagination. Careful consideration of the source material is vital.

Key Themes Explored in “The Book of Lilith”

“The Book of Lilith‚” often encountered in PDF format‚ delves into potent themes of female agency‚ rebellion against patriarchal structures‚ and the exploration of untamed sexuality. Digital versions frequently highlight Lilith’s rejection of subservience to Adam‚ positioning her as a symbol of female independence and self-determination.

Many PDF analyses emphasize Lilith’s connection to the natural world and instinctual drives‚ contrasting her with the more domesticated portrayal of Eve. This exploration of primal feminine power resonates with modern feminist interpretations‚ making the text particularly compelling for contemporary readers.

Furthermore‚ the readily available PDF versions often showcase the myth’s exploration of chaos and the “other‚” challenging conventional notions of good and evil. The text’s enduring appeal lies in its ability to provoke thought and question established norms‚ offering a provocative counter-narrative to traditional biblical stories. Examining these themes within the PDF context is essential.

Lilith as a Symbol of Female Rebellion

Within the digital realm‚ readily available PDF versions of “The Book of Lilith” consistently portray her as a powerful emblem of female rebellion against patriarchal authority. The narrative‚ easily accessible in PDF format‚ details Lilith’s refusal to submit to Adam’s dominance‚ choosing exile over subservience – a radical act for its time.

These PDF texts highlight Lilith’s demand for equality‚ challenging the traditional biblical depiction of women as passive and obedient. Her story resonates with modern feminist thought‚ solidifying her status as a proto-feminist icon. The accessibility of the PDF allows for widespread dissemination of this empowering narrative.

Furthermore‚ the PDF often emphasizes Lilith’s rejection of societal constraints‚ embracing her own desires and autonomy. This defiance of expectations positions her as a figure of liberation‚ inspiring readers to question and challenge oppressive systems. The digital format amplifies her message of rebellion‚ reaching a broader audience.

Lilith and the Concept of Female Sexuality

Accessing “The Book of Lilith” in PDF format reveals a compelling exploration of female sexuality‚ often absent or suppressed in mainstream religious texts. The readily available PDF versions frequently depict Lilith as embodying untamed‚ independent sexual power‚ rejecting the confines of procreation solely for male pleasure.

The narrative‚ easily found as a PDF download‚ portrays Lilith’s agency over her own body and desires‚ a stark contrast to Eve’s portrayal in Genesis. This challenges conventional interpretations of female sexuality as inherently linked to sin or shame. The PDF format facilitates the spread of this alternative perspective.

Moreover‚ the PDF texts often connect Lilith to the natural world and primal instincts‚ suggesting a sexuality rooted in authenticity and freedom. Her story‚ widely circulated in PDF form‚ serves as a reclamation of female desire‚ celebrating it as a source of strength and empowerment. This challenges patriarchal norms and encourages self-acceptance.

Lilith’s Connection to the Natural World and Instinct

Numerous PDF versions of “The Book of Lilith” emphasize her profound connection to the untamed aspects of the natural world‚ portraying her as the embodiment of primal instincts. These readily available PDF documents frequently depict Lilith as the “soul of all beasts‚” representing the raw‚ uninhibited energy of life itself.

The PDF texts highlight Lilith’s association with the wild‚ untamed landscapes – forests‚ deserts‚ and nocturnal realms – symbolizing a rejection of societal constraints and a return to natural rhythms. This connection is often presented as a source of power and liberation‚ accessible through studying the PDF.

Furthermore‚ the PDF versions often explore Lilith’s role as a guardian of instinctual knowledge‚ offering a pathway to reconnect with one’s innate wisdom and intuition. Her story‚ easily disseminated in PDF format‚ encourages embracing the wildness within and honoring the natural cycles of life and death; This resonates with modern ecological consciousness.

Early Christian Symbolism and Lilith

Accessing “The Book of Lilith” in PDF format reveals a fascinating‚ often suppressed‚ history of her interpretation within early Christian thought. While absent from canonical scripture‚ Lilith’s figure permeated folklore and influenced symbolic representations‚ as detailed in many PDF versions.

These PDF documents demonstrate that early Christian writers often equated Lilith with temptation and demonic forces‚ associating her with the dangers of female sexuality and rebellion against divine order. She became a cautionary figure‚ embodying the perceived threat of unchecked female power. The readily available PDFs showcase this negative portrayal.

However‚ some PDF analyses suggest a more nuanced understanding existed‚ with Lilith representing the untamed aspects of the human psyche that needed to be controlled through faith. Exploring these PDF resources reveals how Lilith served as a symbolic foil to the Virgin Mary‚ embodying contrasting ideals of womanhood. The digital availability of these texts allows for deeper investigation.

The Impact of the Lilith Myth on Childbirth Beliefs

Numerous PDF versions of texts surrounding “The Book of Lilith” detail the profound impact of the myth on historical childbirth beliefs. Folklore‚ accessible through these PDF resources‚ reveals widespread anxieties about Lilith’s alleged attacks on pregnant women and newborn infants.

These PDF documents illustrate that protective amulets and rituals were commonly employed to ward off Lilith’s influence during pregnancy and labor. Beliefs centered around Lilith’s desire to steal or harm babies‚ leading to practices intended to safeguard the child. The PDFs showcase the fear surrounding Lilith’s perceived power.

Analysis within these PDFs demonstrates that certain incantations and prayers were recited to appease or repel Lilith‚ reflecting a deep-seated cultural fear. The myth’s influence extended to postpartum practices‚ with measures taken to protect both mother and child from Lilith’s malevolent intentions. Accessing these PDFs provides insight into historical anxieties and protective measures.

Lilith in Modern Literature and Popular Culture

Exploring PDF versions of critical analyses reveals Lilith’s enduring presence in contemporary literature and popular culture. “The Book of Lilith” and related texts‚ often found as PDF downloads‚ have fueled reinterpretations of her character‚ moving beyond traditional depictions of demonic villainy.

These PDF resources demonstrate Lilith’s emergence as a symbol of female empowerment‚ rebellion‚ and sexual liberation. Modern authors frequently utilize her myth to explore themes of female agency and challenge patriarchal norms. The accessibility of these PDFs allows for comparative analysis of diverse interpretations.

Furthermore‚ PDF documents showcase Lilith’s influence in fantasy‚ horror‚ and even romance genres. Her image appears in various media‚ including novels‚ films‚ and video games‚ often reimagined as a complex and sympathetic figure. Examining these PDF analyses highlights how Lilith’s story continues to resonate with contemporary audiences‚ sparking ongoing debate and artistic expression.

Finding “The Book of Lilith” PDF Online: Legality and Sources

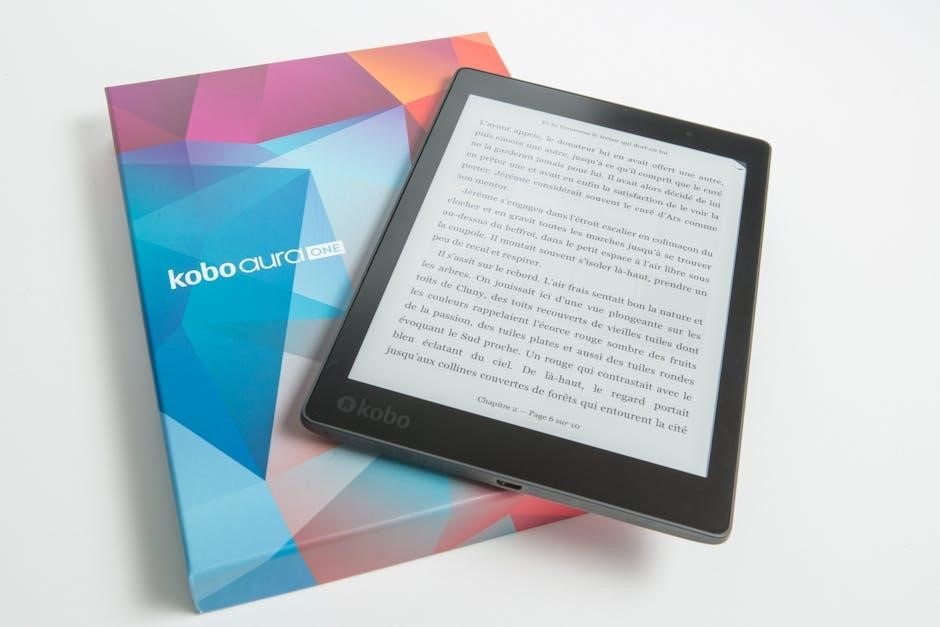

Locating a PDF version of “The Book of Lilith” online presents a complex landscape of legality and source reliability. Numerous websites offer downloads‚ but many operate within legal gray areas‚ potentially infringing on copyright. Accessing legitimate‚ authorized PDF copies is paramount to avoid supporting illegal distribution.

Several online archives and digital libraries may host scanned versions‚ but verifying their licensing and permissions is crucial. Caution is advised when downloading from unverified sources‚ as these often contain malware or compromised files. Searching for PDFs from reputable academic institutions or publishers is recommended.

Furthermore‚ understanding fair use guidelines is essential. Utilizing PDF excerpts for research or educational purposes may be permissible‚ but distributing entire copyrighted works without authorization is illegal; Always prioritize legal and ethical access when seeking “The Book of Lilith” in PDF format‚ ensuring respect for intellectual property rights.

Risks Associated with Downloading PDFs from Unverified Sources

Downloading a PDF of “The Book of Lilith” from unverified sources carries significant risks‚ extending beyond potential copyright infringement. These platforms often serve as breeding grounds for malware‚ viruses‚ and other malicious software that can compromise your device and personal data. Hidden within seemingly harmless PDF files‚ these threats can lead to identity theft‚ financial loss‚ and system instability.

Furthermore‚ unverified sources frequently lack adequate security protocols‚ making your download activity vulnerable to interception and monitoring. This poses a privacy risk‚ potentially exposing your IP address and browsing history. The quality of the PDF itself is also questionable; scans may be incomplete‚ illegible‚ or contain errors.

Prioritizing downloads from reputable websites‚ academic institutions‚ or authorized publishers significantly mitigates these risks. Employing robust antivirus software and exercising caution when clicking links or downloading files are essential safeguards. Protecting your digital security is paramount when seeking access to “The Book of Lilith” in PDF format.

Notable Female Figures in the Bible: Lilith‚ Jezebel‚ and Mary Magdalene

Examining Lilith alongside figures like Jezebel and Mary Magdalene reveals a pattern of complex female representation within biblical narratives and subsequent interpretations. While Lilith doesn’t appear in the canonical Bible‚ her legend‚ often explored in texts like “The Book of Lilith‚” highlights a rebellious spirit absent in Eve’s traditional portrayal. Jezebel‚ frequently condemned for her religious practices and political influence‚ similarly embodies a powerful‚ yet vilified‚ female presence.

Mary Magdalene‚ historically misrepresented as a repentant prostitute‚ is undergoing re-evaluation as a significant disciple and potential leader within early Christian communities. These women‚ often labeled “scandalous‚” challenge conventional interpretations of biblical womanhood.

The exploration of these figures‚ and the search for resources like a “The Book of Lilith” PDF‚ reflects a growing interest in reclaiming marginalized female voices and questioning patriarchal narratives. Understanding their stories provides a richer‚ more nuanced perspective on the biblical landscape and the enduring power of female archetypes.